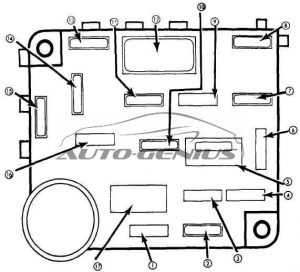

Mercury Cougar XR-7 (1980 – 1982) – fuse box diagram

Year of production: 1980, 1981, 1982

Fuse box diagram

| № |

A |

Protected Component |

| 1 | 5 | Instrument lights and interior light |

| 2 | 10 | Throttle solenoid, seat belt warning buzzer |

| 3 | — | — |

| 4 | 20 | Horn and cigar lighter |

| 5 | 20 | Circuit Breaker: Power seats and door locks |

| 6 | 20 | Choke heater |

| 7 | 15 | Courtesy lights, clock feed, key warning buzzer, headlight warning buzzer, seat back latch relay and illuminated entry |

| 8 | 15 | Standard: Parking, tail and license lights |

| 10 | Console: Parking, tail and license lights | |

| 9 | — | — |

| 10 | 20 | Radio, power antenna and CB radio |

| 11 | 20 | Accessories, air conditioning clutch, heated rear window relay coil, deck lid release, speed control and illuminated entry |

| 12 | 6 | Circuit Breaker Windshield wipers and wiper/washers |

| 13 | 15 | Stop and hazard warning lights |

| 14 | 15 | Turn signal and back-up lights |

| 15 | 30 | Air conditioning and automatic temperature control blower |

| 16 | — | — |

| 17 | 20 | Power windows |

Circuit Breaker:

Fusible Links:

In-Line Fuse:

|

||

WARNING: Terminal and harness assignments for individual connectors will vary depending on vehicle equipment level, model, and market.